China has Overtaken Germany in the use of Robots in Industry an Annual Report Published by the International Federation of Robotics (IFR) Showed on Wednesday

China Overtakes Germany in Industrial Use of Robots Says Report

BERLIN, Nov 20 (Reuters) China has overtaken Germany in the use of robots in industry, an annual report published by the International Federation of Robotics (IFR) showed on Wednesday, underscoring the challenges facing Europe's biggest economy from Beijing.

In terms of robot density, an important indicator for international comparisons of the automation of the manufacturing industry, South Korea is the world leader with 1,012 robots per 10,000 employees, up 5% since 2018, said the IFR.

Singapore comes next, followed by China with 470 robots per 10,000 workers - more than double the density it had in 2019.

That compares with 429 per 10,000 employees in Germany, which has had an annual growth rate of 5% since 2018, said IFR.

"China has invested heavily in automation technology and ranks third in robot density in 2023 after South Korea and Singapore, ahead of Germany and Japan," said IFR president Takayuki Ito.

China’s booming robotics market could be traced to robust domestic demand and strong policy support, according to the government.

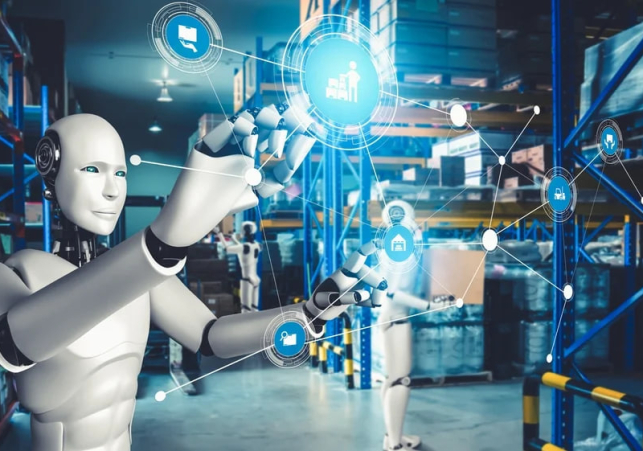

Robots are now used across vast sectors of China’s economy, including manufacturing, logistics, hospitality, healthcare and construction.

“China’s automobile industry is now the largest in the world, which is also a boon to Chinese robotic adoption, as the auto industry is a major purchaser of industrial robots,” Atkinson said.

The ITIF report also pointed out that China’s robotics industry still relied heavily on foreign technologies, and remained dependent on many imported parts that were predominantly made by companies in Japan, Germany and Switzerland.

Despite the positive growth, Atkinson noted two areas that China still lags in.

First is software, which constitutes about 80 per cent of a robot’s value and is a key differentiator of robot quality and versatility, was a weak point for Chinese companies, he said.

The other was innovation. Many automation products from China resembled those of Fanuc in Japan or Boston Robotics in the US, indicating an inclination to imitate over original development.

The report estimated that it could also create jobs by boosting productivity and real income and spending levels, creating an additional 90 million jobs by 2037.

But some demographers doubt automation’s ability to counter the country’s labour problems.

“Automation helps upgrade manufacturing and the supply chain, but it does little to help domestic consumption and the ageing problem,” said independent demographer Huang Wenzheng.

In the long run, a shrinking population is more likely to lead to a relative decline in gross domestic product per capita and extraordinary talent, he added.

The panda robot and the five stars on the red production line represent China and its manufacturing industry. They are both symbols of China.

The author expresses a positive attitude towards the use of industrial robots in the workplace, as depicted by the panda crossing its arms with a smile on its face while overseeing the machines’ operations.

Chart

China is projected to experience a significant decline in its working-age population over the next two decades.

By 2030, the working population is expected to decrease by 26 million by 2050, a further decline of 148 million is anticipated.

In contrast, other major regions like Africa, India, and the US will witness an increase in their working-age populations during the same period.

Africa, in particular, is projected to add 206 million individuals to the workforce by 2030, with an additional 560 million expected by 2050.

With a low fertility rate and an ageing population, China is projected to experience a significant decrease in its working-age population over the coming decades, potentially reducing its competitiveness.

Meanwhile, regions like India and Africa, which will see substantial increases in their working-age populations, stand to benefit from economic growth and industrial advancement.

In response to these demographic changes and challenges, China has prioritised automation and widely adopted industrial robots.

It aims to address the anticipated labour shortage and mitigate potential geopolitical complications while safeguarding its competitiveness and status as the world’s factory. (accept other reasonable answers)

Germany has in the past relied heavily on its industrial base and exports for growth but is facing ever tougher competition from countries like China.

It expects economic contraction for the second year running in 2024, making it the worst performer among the Group of Seven rich democracies.

The key reason for China’s automation trend is that it needs to maintain its robust industrial system and compete with emerging markets.

Placing robots in a leading role helps China address this need by enhancing its industrial efficiency, productivity, and competitiveness.

By leveraging robotics and automation, China can adapt to the labour shortages associated with the changing demographics, ensuring its position as the world’s factory.

To a large extent, I agree with Huang’s view that automation may not effectively address the challenges posed by the changing labour market.

The estimate that technology could displace 26 per cent of jobs in China over the next two decades raises concerns about income inequality and reduced purchasing power for affected individuals, which could impact domestic consumption.